-

Empty cart

No products in the cart.

Return to Shop

Product description

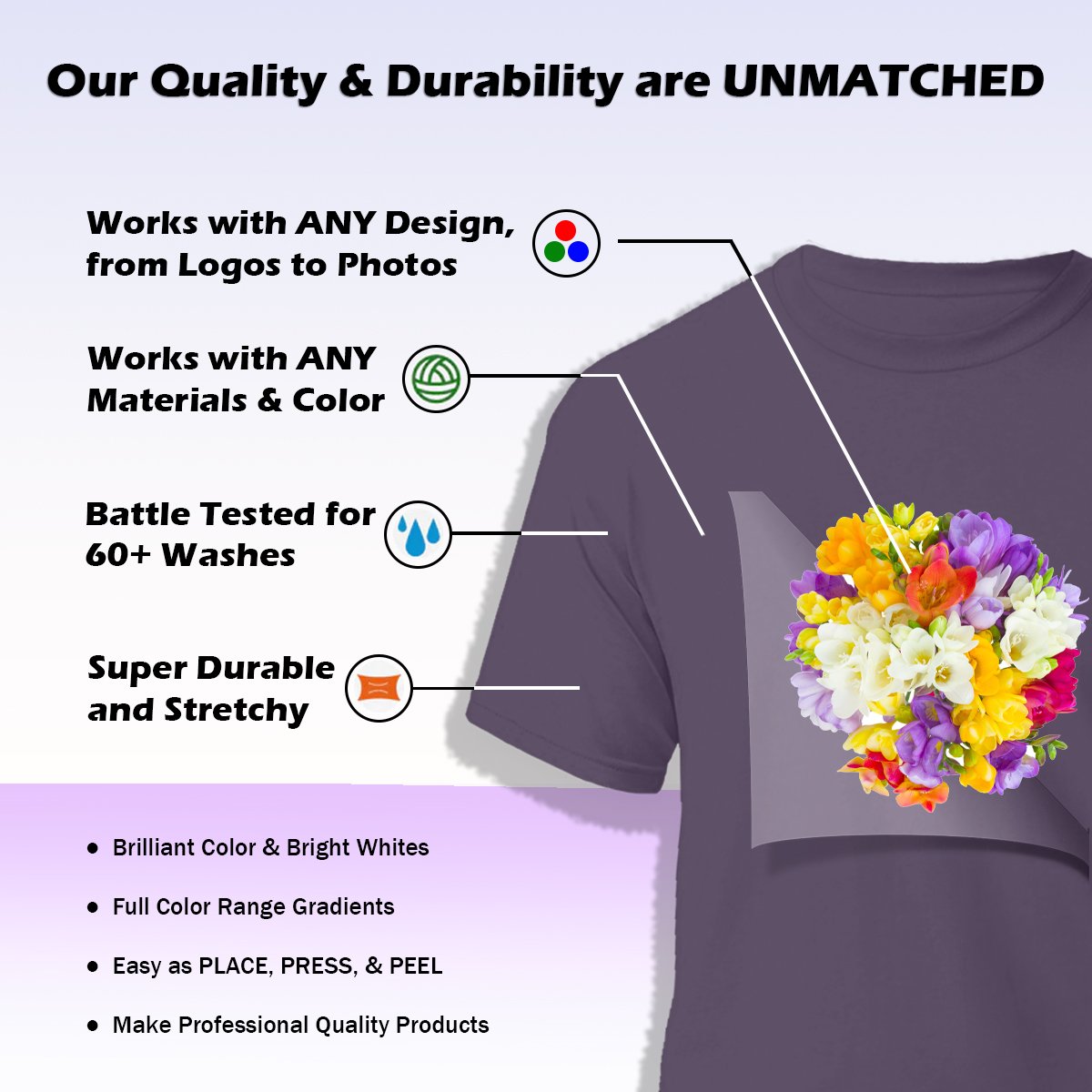

Features:

- After baking the powder, solid white for more vibrant colors

- Even and regular particles for quality graphics and good adherence

- Finely coated film means no pinholes!

Sizes:

- 1 lb

- 1 kg

- 20 kg

Product Specs

Product Specs

Instructions (for use with DTF Station Warm Peel film):

- Print the image onto the matte side of the film in mirror mode. (CMYK>>White Ink)

- Apply hot melt powder evenly and remove the excess powder.

- Hover with a heat press to bake the hot melt powder (340°F, 5min). Or use a curing oven (300-315 °F, 1min).

- Transfer the image by heat press at 330°F for 15sec with medium pressure.

- After the first press, Option 1: Wait for 4-6 seconds and remove the film gently Option 2: Rub the top surface with a cloth to remove some heat and peel off the film gently

- Heat press again at 330°F 5-10sec with medium pressure to enhance softer hand feel.

- The basic concept for DTF is to print CMYK first then WHITE on top of it. ALWAYS MIRROR YOUR IMAGE FIRST!

- Most of you will be printing onto standard A3 and A4 sheets. Utilize every inch of space as you can to save on time and cost of materials. We call that gang sheeting. One benefit of GC is that it allows multiple images to be uploaded at the same time for printing. Those who order Plastisol Transfers will already know this. The two most common platens I use are 10 x 12 (A2) and 16 x 20 (A3). I place the sheet towards the top middle as a guide and measure how much empty space I have on the sides and bottom because the sheets will be smaller than your platen. I use tape to hold in at least 2 corners to prevent the sheet from shifting while printing.

- Using GC for DTF is very much the same as with DTG. The only difference is you are reversing the CMYK/white color process and mirroring your image.

- If your image has black in it then click on Black Garment. That will prevent GC from printing black unnecessarily.

- For all other colors including white, use (Dark Color).

- After selecting the proper color choice, you need to tinker with your color and white levels. For me personally I use level 2 for color and level 1 for white. I leave ink density to zero. And make sure you leave enough time in between passes in Pause between Passes (sec). This is very important. I like to choose 30-60 seconds

- Under White Management it is very important to check “OFF” first before you print your CMYK pass. This will allow your color layer to go down first.

- After your color pass is done then you go back to white management and click “ON”. Be sure you have enough seconds in your “Pause between passes (sec)” or else your printer will print another CMYK pass right after your white pass. YOU DO NOT WANT THAT! So you MUST manually press cancel on your printer before it does so.

- Powder should NOT be applied on the printer platen. It needs to be applied AWAY from the printer. Application near the printer increases the risk of printer damage if the printer “breathes” in the adhesive powder into the intake fan by the electronics near the back of the machine. Damage to the printer for inappropriate use may not be covered under warranty.

- Please wear Personal Protective Equipment (eyeglasses, mask, and gloves) when working with DTF products. The fumes from curing the powder can be hazardous.

Reviews

Reviews

Add a review

Currently, we are not accepting new reviews

0.0

Based on 0 reviews

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

0 of 0 reviews

Sorry, no reviews match your current selections

Instructions (for use with DTF Station Warm Peel film):

- Print the image onto the matte side of the film in mirror mode. (CMYK>>White Ink)

- Apply hot melt powder evenly and remove the excess powder.

- Hover with a heat press to bake the hot melt powder (340°F, 5min). Or use a curing oven (300-315 °F, 1min).

- Transfer the image by heat press at 330°F for 15sec with medium pressure.

- After the first press, Option 1: Wait for 4-6 seconds and remove the film gently Option 2: Rub the top surface with a cloth to remove some heat and peel off the film gently

- Heat press again at 330°F 5-10sec with medium pressure to enhance softer hand feel.

- The basic concept for DTF is to print CMYK first then WHITE on top of it. ALWAYS MIRROR YOUR IMAGE FIRST!

- Most of you will be printing onto standard A3 and A4 sheets. Utilize every inch of space as you can to save on time and cost of materials. We call that gang sheeting. One benefit of GC is that it allows multiple images to be uploaded at the same time for printing. Those who order Plastisol Transfers will already know this. The two most common platens I use are 10 x 12 (A2) and 16 x 20 (A3). I place the sheet towards the top middle as a guide and measure how much empty space I have on the sides and bottom because the sheets will be smaller than your platen. I use tape to hold in at least 2 corners to prevent the sheet from shifting while printing.

- Using GC for DTF is very much the same as with DTG. The only difference is you are reversing the CMYK/white color process and mirroring your image.

- If your image has black in it then click on Black Garment. That will prevent GC from printing black unnecessarily.

- For all other colors including white, use (Dark Color).

- After selecting the proper color choice, you need to tinker with your color and white levels. For me personally I use level 2 for color and level 1 for white. I leave ink density to zero. And make sure you leave enough time in between passes in Pause between Passes (sec). This is very important. I like to choose 30-60 seconds

- Under White Management it is very important to check “OFF” first before you print your CMYK pass. This will allow your color layer to go down first.

- After your color pass is done then you go back to white management and click “ON”. Be sure you have enough seconds in your “Pause between passes (sec)” or else your printer will print another CMYK pass right after your white pass. YOU DO NOT WANT THAT! So you MUST manually press cancel on your printer before it does so.

- Powder should NOT be applied on the printer platen. It needs to be applied AWAY from the printer. Application near the printer increases the risk of printer damage if the printer “breathes” in the adhesive powder into the intake fan by the electronics near the back of the machine. Damage to the printer for inappropriate use may not be covered under warranty.

- Please wear Personal Protective Equipment (eyeglasses, mask, and gloves) when working with DTF products. The fumes from curing the powder can be hazardous.

Categories: DTF Film & Powder, DTF Supplies

Related Products

Related Products

DTF Printer 24 Inch with Dual I3200 XP600 Print Head

$13,999.00DTF Printer 24 Inch with Dual I3200 XP600 Print Head Heat Direct Transfer Film 60CM DTF Printer with Powder Shaker for T shirt

T-Shirt Ruler Guide

$3.99This 8 piece ruler guide is the perfect tool for t-shirt alignment and placement. The clear plastic flexible ruler can align with the collar of the t-shirt to ensure accurate placement of the transfer or vinyl every time.

T-Shirt Folding Board

$4.25T-Shirt Folding Board – Folding your shirts just got easier! After a long day of printing, this makes the most boring part easy and quick. Our folder is designed to cut your time in half, each shirt takes roughly 3 seconds. Your clients will be happy with their perfectly printed wrinkle-free tees.

DTF Gang Sheets

$16.99 – $64.99DTF Full Color Transfers

WALAKustom DTF Direct to Film Full Color Transfers are soft full color transfers that can be pressed on most fabrics! There are no quantity minimums on these transfers-so you can order single orders to super large orders. WALAKustom Full Color Transfers are suitable for cotton, poly, cotton, polyester, and most fabrics with recommended test press.

- Transfer sheets

- 22″ x 24″

- 22″ x 36″

- 22″ x 48″

- 22″ x 72″

- 22″ x 96″

- Ganging allowed!

- Your design cannot be bigger than the sheet size you selected.

- Artwork will be sized to the max sheet size unless otherwise specified

- Any details smaller than 1 point (0.35mm) will have a colored outline/backing (matching the intended garment color) added by production.

- Your design cannot be bigger than the sheet size you selected.

- Artwork will be sized to the max sheet size unless otherwise specified.

- Copyright material is NOT permitted (without written documentation).

- Not suitable for iron or handheld press.

- No quantity minimums

- 1-2 business days turnaround time before shipment

- Full Color

- Crisp defined edges

- Great for small orders

- PEEL WARM

- No Cutting or Weeding

- Suitable for all fabric types

DTF Film Rolls (Cold/Warm Peel)

$59.99 – $84.99- High Ink Loading Layer: You can lay down more color / white to create rich colored decorated DTF prints.

- Hot Peel: Peel off the film without a long wait after the first press.

- Single Side Matte: Easily distinguish the print side.

- Compatible with: Any DTF printer on the market (Recommended use with a roll printer)